How industrial panel PCs are accessed?

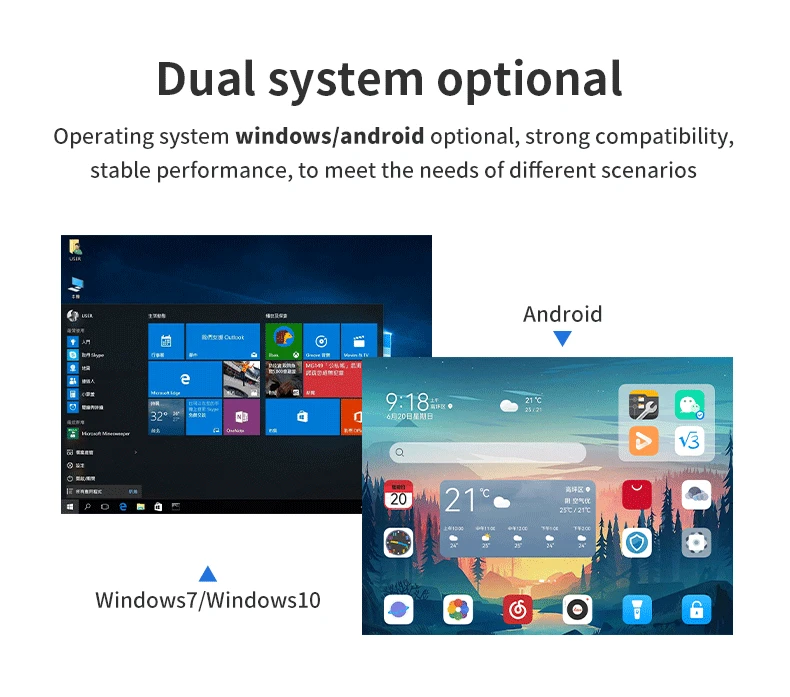

Industrial panel PCs can be accessed through various methods, depending on the specific configuration and setup. Here are some common ways to access an industrial panel PC: Touchscreen Interface: Many industrial panel PCs come with built-in touchscreens, allowing users to directly interact with the device by tapping or swiping on the screen. The touchscreen interface typically provides access to the installed applications and operating system functionalities. Keyboard and Mouse: Some industrial panel PCs are equipped with USB ports or other input interfaces, enabling the connection of external keyboards and mice. This setup allows users to navigate and interact with the panel PC using traditional input devices. Remote Desktop Protocol (RDP): Industrial panel PCs that run on Windows operating systems often support Remote Desktop Protocol. This allows users to access the panel PC remotely from another device, such as a desktop computer or laptop, over a network connection. RDP provides a graphical interface and enables full control of the panel PC as if you were physically present. VNC (Virtual Network Computing): VNC is a cross-platform remote desktop protocol that allows you to access and control industrial panel PCs from various devices, including computers, smartphones, and tablets. By installing a VNC server on the panel PC and a VNC client on the accessing device, you can establish a remote connection and interact with the panel PC’s desktop environment. Web-based Interface: Some industrial panel PCs offer web-based interfaces that can be accessed through a web browser. These interfaces provide a user-friendly dashboard with controls and options to manage and monitor the panel PC’s functions and settings. You typically access the web interface by entering the panel PC’s IP address or hostname in the browser’s address bar. Serial Console: In certain cases, an industrial panel PC may provide a serial console interface for access…