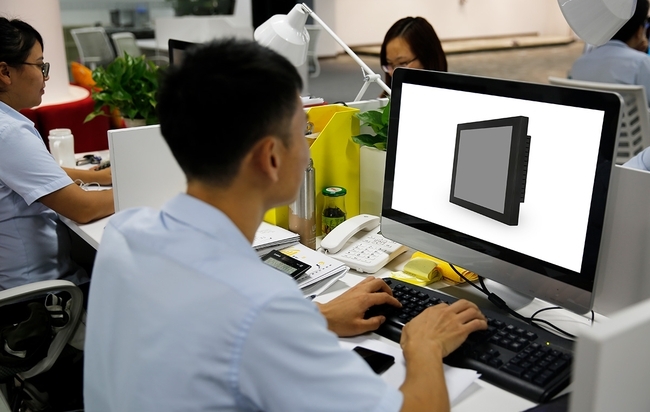

Industrial panel PC/monitor used on the Bank self-service terminal

Full wireless network coverage, smart number calling machines, tablet computers to inquire product and business information, touch-to-fill forms instead of manual forms, self-service card issuance… In more and more bank outlets, citizens have deeply felt the intelligentization of banking equipment Convenience The visual counter can directly “talk” The visual counter, also known as VTM (VirtualTellerMachine, remote virtual teller machine), is currently equipped in many bank branches in the urban area. It has innovated the service mode of traditional bank single equipment and single counter. It has 24-hour service and traditional self-service equipment. The cash transactions complement each other’s advantages and provide full-featured retail business services. In the Linyi branch of China Merchants Bank, the reporter saw two video counters in the self-service area of the bank lobby. The visual counter is equipped with functional modules such as ID card recognizer, camera, card reader, QR code scanning, etc. Users can directly use video to talk and consult with bank employees who serve customers at the device terminal, and handle card application, transfer and remittance , Loss reporting, query, password modification, debit card activation and other non-cash services. For users who urgently need to handle non-cash services, some services that must be authenticated can be handled at the self-service visual counter. In the case of a large number of people in line at the counter, it can greatly shorten the time for handling business. The self-service payment machine never closes The payment of utility bills is a payment service that most urban residents must go through. In order to facilitate the payment of utility bills for citizens, many banks are also equipped with self-service payment machines at bank branches to facilitate the payment of residents in surrounding communities. Many community bank branches of Minsheng Bank have set up self-service payment machines for…